Sasquatch

Well-known member

- Joined

- Dec 14, 2008

- Messages

- 991

- Reaction score

- 1

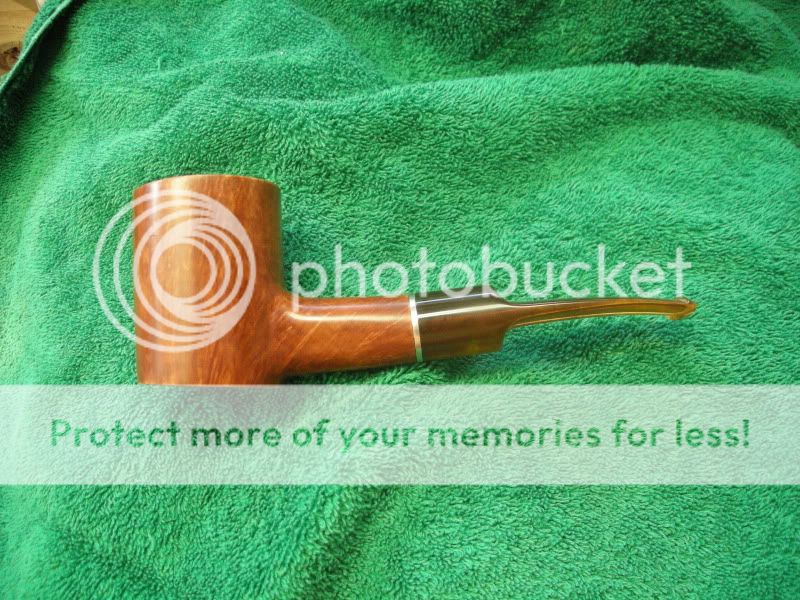

I'm sure details vary greatly, but I thought it might be fun for you guys to see how a pipe goes from chunk of wood to finished pipe.

In this pic, I've got the appropriate piece selected (trying to make a rather classic "pot") and have started to cut it down a bit, making sure the grain is good and the briar is not pitty or soft or whatever.

Once I'm satisfied with that, the pipe is drawn on the block, some angles cut to control the drilling angles and final shape of the pipe, lines of basic shape, and the thing is drilled.

That's about an hour well wasted. More to come in the next few days.

In this pic, I've got the appropriate piece selected (trying to make a rather classic "pot") and have started to cut it down a bit, making sure the grain is good and the briar is not pitty or soft or whatever.

Once I'm satisfied with that, the pipe is drawn on the block, some angles cut to control the drilling angles and final shape of the pipe, lines of basic shape, and the thing is drilled.

That's about an hour well wasted. More to come in the next few days.